Digitalize production.

Elevate efficiency.

Evocon is a visual and user-friendly OEE software that helps manufacturing companies improve productivity and remove waste as they become better.

30-day free trial. No financial commitment

Trusted choice by manufacturers worldwide

rating based on

Capterra user reviews

4.9 rated customer

service you can rely on

Your data is secured with

ISO 27001 System Certification

Software features

OEE software. Easy to use Easy to understand.

Software features

We help you better your world.

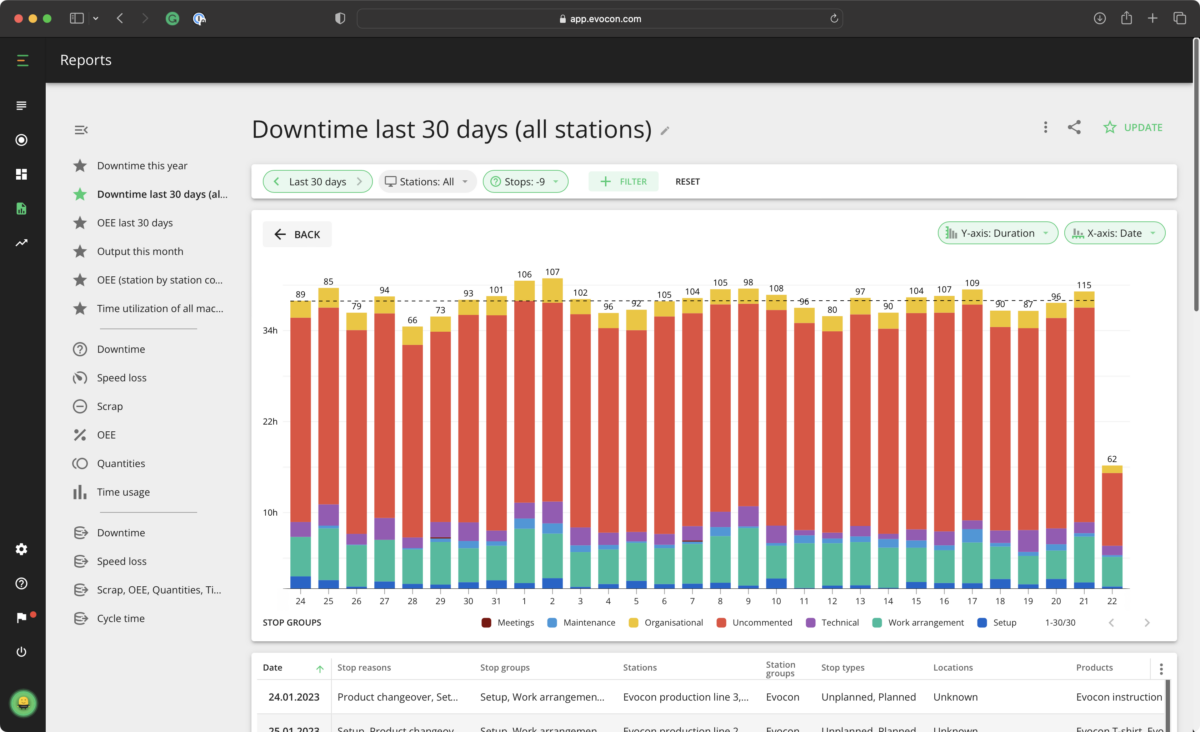

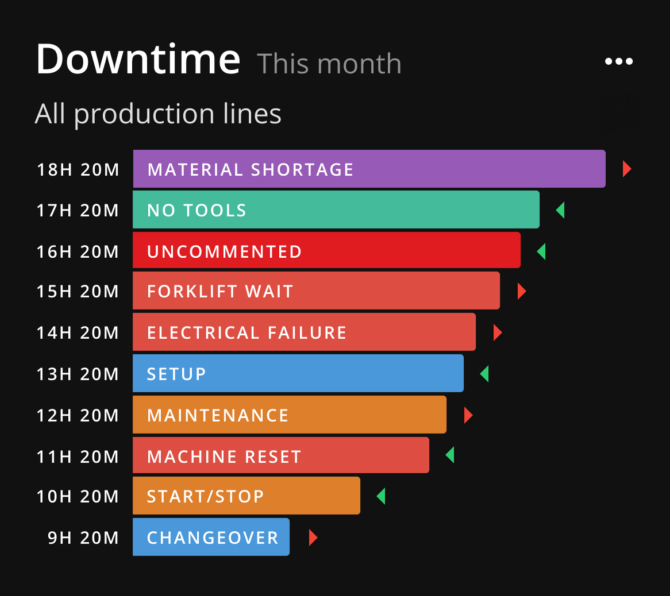

Track machine downtime

Clearly understand how much downtime you have and why and what are the improvement areas.

Get insight into production performance in real-time

Understand how your production process is performing against expectations and how much potential is unused.

Create a platform for change

Evocon provides you with the tools you need to initiate and sustain cultural change.

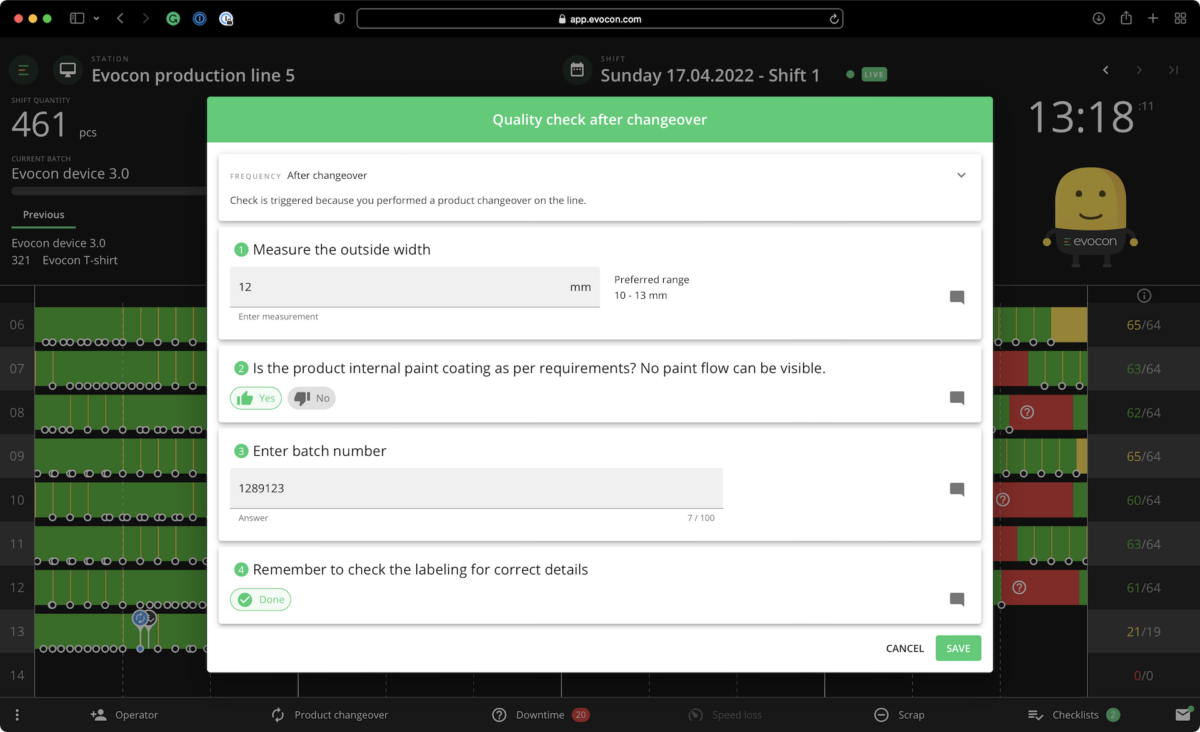

Engage operators with their work

By giving visual feedback to your operators, you increase productivity and enhance communication.

Automate data collection

Kickstart your digital transformation with Evocon

30-day free trial

No financial commitment.

Start your improvement journey by trying out Evocon for free in your factory.

The Recipe for Success: Operational Excellence at Equatorial Coca-Cola Bottling Company

7 min read | December 15, 2023

Equatorial Coca-Cola Bottling Company (ECCBC), the bottling partner of The Coca-Cola Company across North and West Africa, is at the forefront of producing, commercializing, and distributing a portfolio of cherished…